It’s been less than a week since listeria was found in a popular deli meat, leading to a recall that now includes over 7 million pounds of ready-to-eat meat and poultry products, covering 71 separate items.

This isn’t just deli meat. Each year, 48 million people, or 1 in every 6, get sick from compromised food products. That’s more than 16% of the U.S. population. Of that number, 128,000 are hospitalized, and 3,000 die. According to recent data from the Centers for Disease Control and Prevention, this percentage has grown 2% from years prior.

The Food Safety Modernization Act (FSMA), passed in 2011, includes a traceability compliance rule that will go into effect on January 20, 2026. At that time, each link on the “Cold Chain” of safe food transportation will have to track certain high-risk food ingredients such as fresh fruits and vegetables, eggs, nut butters, cheeses, and seafood products.

Key Requirements of Food Safety

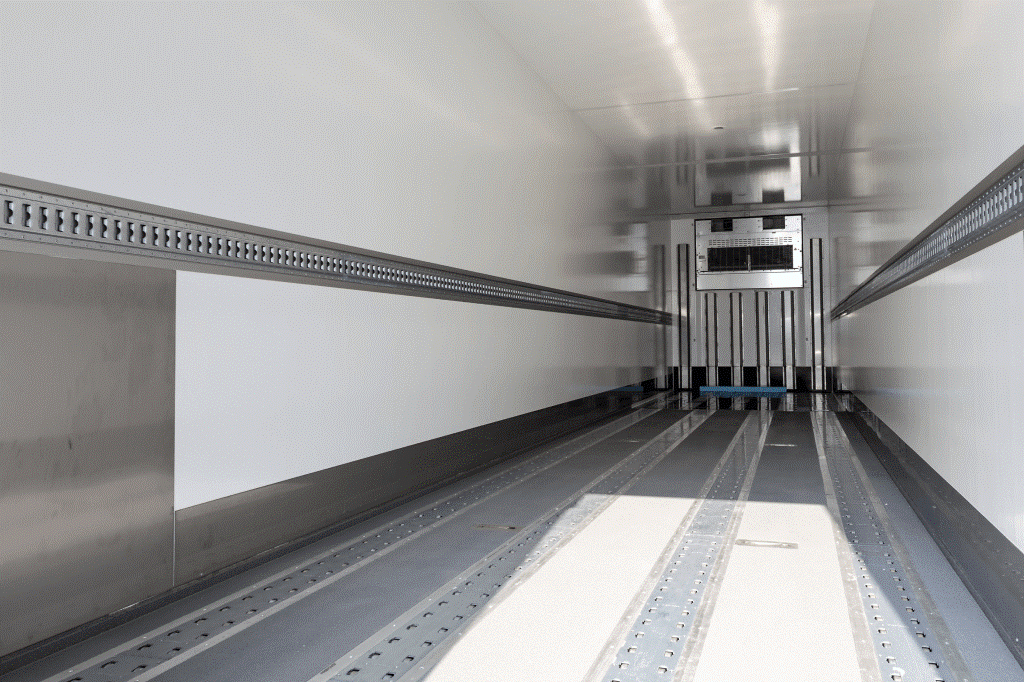

- Vehicles and transportation equipment: The design and maintenance of vehicles and transportation equipment must ensure that they do not cause the food they transports to become unsafe. For example, they must be suitable and adequately cleanable for their intended use and capable of maintaining temperatures necessary for the safe transport of food.

- Transportation operations: The measures taken during transportation to ensure food safety include adequate temperature controls, preventing contamination of ready to eat food from touching raw food, protecting food from contamination by non-food items in the same load or previous load, and protection of food from cross-contact, such as the unintentional incorporation of a food allergen.

- Training: Training of carrier personnel in sanitary transportation practices and documentation of the training are required when the carrier and shipper agree that the carrier is responsible for sanitary conditions during transport.

- Records: Maintenance of records of written procedures, agreements, and training is required of carriers. The required retention time for these records depends on the type of record and when the covered activity occurred, but does not exceed 12 months.

Safely Delivering Your Refrigerated Goods With Consistent Reliability

The company loading the refrigerated vehicle with temperature-controlled cargo consisting of human or animal food is responsible for ensuring the vehicles are clean before each loading.

While this Safety Bulletin is not a complete guide to the sanitary transportation of food, these guidelines may help those responsible for transporting food product free of food-borne

pathogens. Workers loading and unloading refrigerated cargo must be properly trained in the best practices for cleaning the inside of the refrigerated compartment. Workers assigned to clean vehicles are responsible for following the cleaning SOPs outlines by their respective company and documenting the cleaning was done. Workers should notify their supervisor if they have any questions or notice safety issues they do not know how to address.

Daily Best Practices to Mitigate Food-Borne Pathogens

- Select an area for cleaning vehicles free from environmental concerns

- Open the doors of the refrigerated compartment and remove any items that should not get wet. Sweep out debris or blow out compartment with an air hose.

- Carefully clear any and all debris (paper, plastic wrap) from the compartment and inspect the evaporator housing to remove any debris.

Recommended Practices When Cleaning Refrigerated Compartment

- Be certain to remove debris before mixing water.

- Prepare bucket of food-grade detergent by mixing.

- Wipe down interior surfaces with clean cloth and detergent-water mixture.

- Use hose and water to spray inside compartment. Make sure to spray ceiling and walls as well as floor. Give special attention to cracks, crevices, and areas near door openings and pockets. All cleaning steps should follow a top-down or “top first, bottom last” approach.

- Scrub inside compartment with clean cloths and/or brushes using detergent.

- Rinse inside the compartment. Make sure to spray the ceiling, walls and floor. Give special attention to cracks and crevices, and areas near door openings.

- Allow the inside of the compartment to air dry.

- Shut the doors and/or take other steps, as necessary, to keep your vehicle clean. Always follow the Daily Best Practices above and ensure no debris is left in the compartment at the end of day.

- When dirty, wash the outside of truck.

Loading Procedure Checklist

☐ Pre-cool the compartment prior to loading.

Download the Idealease Quick- Guide to Proper Product Loading

Airflow in and around your refrigerated cargo is critical to avoid devastating illness due to inadequate cooling. Just like your refrigerator at home, if loaded improperly and blocking airflow you risk spoiling food.

Scan this QR code for a quick-guide to properly loading refrigerated products to ensure the safety of the food delivered.

CVSA's Brake Safety Week Scheduled for August 25-31

The Commercial Vehicle Safety Alliance (CVSA) has announced Aug. 25-31 as the dates for this year’s Brake Safety Week.

Brake Safety Week is a commercial motor vehicle and driver inspection and regulatory compliance enforcement initiative, a brake-safety awareness and outreach opportunity, and a brake-related inspection and violation data-collection project.

Inspection and Enforcement

CVSA-certified inspectors will conduct routine commercial motor vehicle inspections throughout the week, focusing on brake systems and components. Commercial motor vehicles found to have brake-related out-of-service violations will be removed from roadways until those violations are corrected.

For this year’s Brake Safety Week, inspectors will focus on the condition of brake linings and pads. Brake lining and pad issues may result in vehicle violations and could affect a motor carrier’s safety rating.

In addition, some jurisdictions have performance-based brake testers (PBBT) and will be using them during Brake Safety Week. A PBBT is a machine that assesses the braking performance of a vehicle.